Dr. Thomas Aubert, France: Dr. Increasing OR throughput with robotic-assisted surgery

At Hôpital de la Croix Saint-Simon in Paris, Dr. Thomas Aubert has always been driven by a single question: How can surgical care be delivered efficiently without compromise?

After nearly a decade of performing navigated total knee replacements (TKRs), he transitioned to robotic-assisted surgery in June 2024. For him, this wasn’t a dramatic shift, but a natural evolution rooted in precision, reproducibility in surgery, and thoughtful surgical workflow optimization.

Rather than disrupting his workflow, robotic-assisted surgery became an enabler that strengthened the operating room efficiency he had already built. Integration was smooth, and the impact was immediate.

A rhythm that sets the pace for the team

Each OR day follows a clear and steady cadence, creating momentum without pressure. Roles are well-defined, transitions are smooth, and unnecessary stops are avoided.

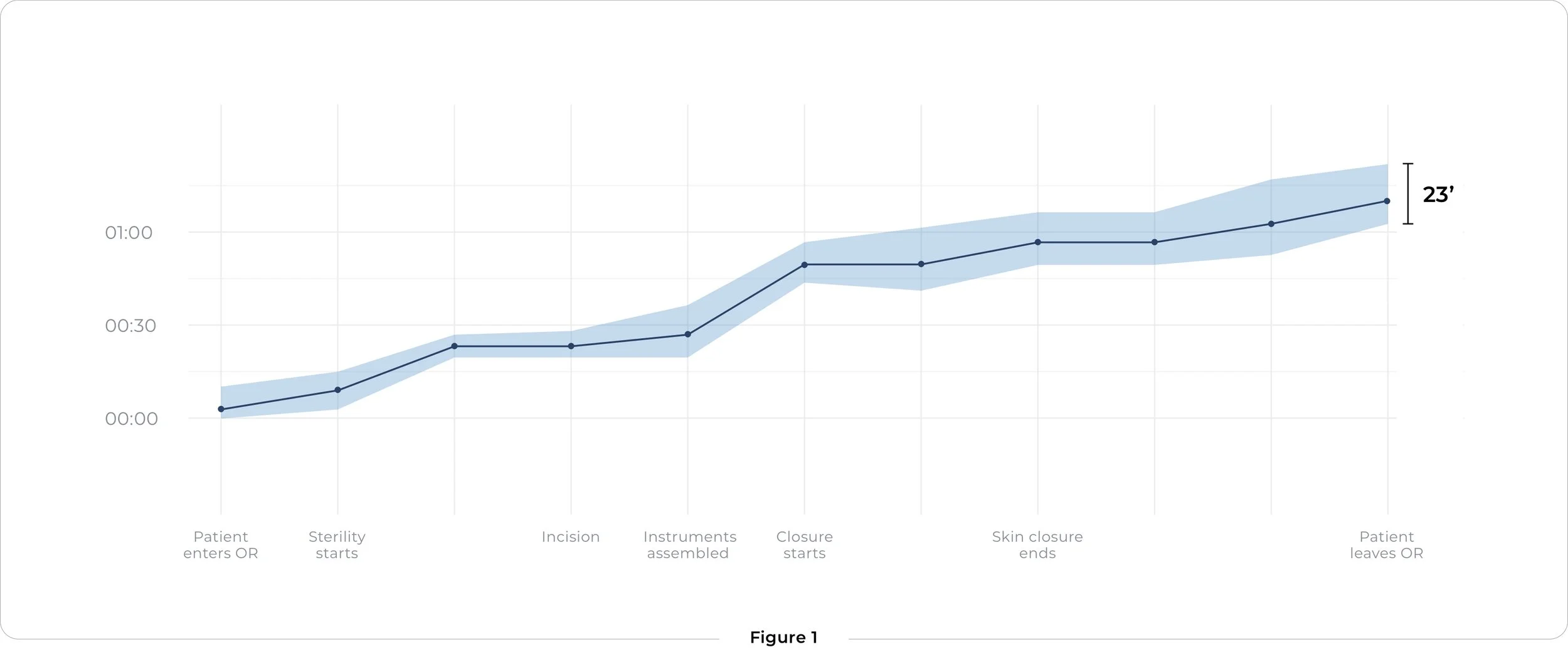

Using the DEO.care digital twin platform, Dr. Aubert’s OR workflow was mapped and analyzed in detail. The analysis confirmed what the team already knew: the workflow functions as a well-aligned system.

By coordinating robot setup, patient preparation, and material workflows in parallel, the OR maintains momentum throughout each case. Robotic-assisted surgery reinforces this foundation by making the overall workflow more predictable. Consequently, it contributes to a work environment where efficiency supports focus, collaboration, and sustained performance across the day.

Next step: increasing throughput with DEO.care

After confirming the robustness of his surgical flow, DEO.care’s collaboration with Dr. Aubert moved to the following question:

Where can we achieve OR throughput optimization without disrupting quality or rhythm?

To answer this, DEO.care performed on-site measurements in Dr. Aubert’s operating room, collecting detailed process data to identify further opportunities for continuous improvement. These measurements were fed into a digital twin simulation using DEO.care’s platform, allowing different workflow scenarios to be tested without disrupting live operations.

The simulation highlighted improvement potential in two key areas:

Reduce variability in cleaning activities during turnover

Reduce turnover time between two patients by defining the optimal trigger points to call in the next patient.

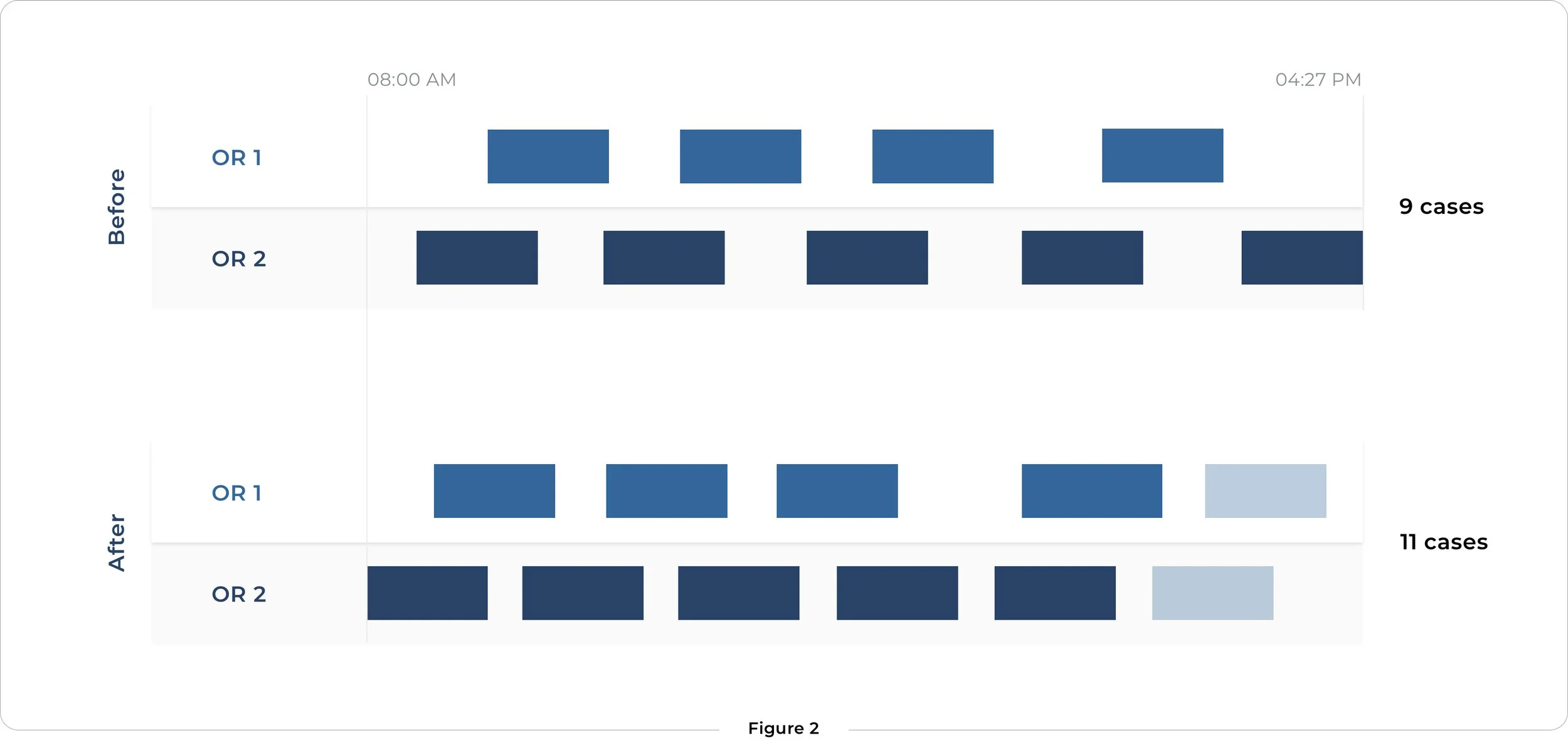

Instead of just theory, the digital twin simulations showed real potential. By stabilizing turnover activities and aligning patient call-in timing more precisely, Dr. Aubert could add two additional joint replacement cases within the same OR time window.

Based on these insights, DEO.care delivered concrete, step-by-step workflow guidance to support implementation in daily practice. The impact of these adjustments was later measured during a dedicated operating day. Measurements confirmed that the optimized workflow could be applied consistently and sustainably, without increasing pressure on the team or disrupting the established surgical rhythm.

The results were clear. With the optimized workflow in place, Dr. Aubert has been able to increase surgical capacity from nine to eleven joints in flip rooms on a typical operating day. And this without extending the operating hours.

Importantly, the same calm cadence, predictability, and team alignment were preserved. This case clearly reinforces that teams can achieve higher throughput without compromising quality or working conditions.

For Dr. Aubert, the value extends beyond efficiency metrics. Better turnover optimization means more patients can benefit from his team’s expertise, while preserving the collaborative, low-stress environment that defines his OR.